3D printing

What is 3D printing?

3D printing is a process of creating three-dimensional objects using digital designs. It is also known as additive manufacturing, as it builds the object layer by layer. The process starts with the creation of a 3D design in a modeling software. This design is then used to create a 3D model, which is then used to create a 3D printing file. This file is then sent to the printer, which prints the object layer by layer. The materials used for 3D printing can be a variety of plastics, metals, ceramics, and even food. Depending on the printer, the objects can be printed with a high level of detail, accuracy, and strength.

3D printing offers various advantages over traditional manufacturing processes. It is cost effective when compared to traditional machining or molding processes. It is also faster, as objects can be printed in a fraction of the time it would take to produce them using traditional methods. Additionally, 3D printing can produce objects with intricate designs, which would be impossible to create using traditional machining methods.

3D printing is being used in a variety of industries, such as automotive, aerospace, medical, and consumer products. In the automotive industry, 3D printing is being used for creating car parts, such as fuel pumps and air intakes. In the aerospace industry, 3D printing is being used to create components for rockets and satellites. In the medical field, 3D printing is being used to create prosthetics, implants, and other medical devices. In the consumer products industry, 3D printing is being used to create products such as toys, jewelry, and even furniture.

Overall, 3D printing is a revolutionary technology that has the potential to revolutionize the way objects are manufactured. With its speed, accuracy, and cost-effectiveness, 3D printing is quickly becoming an integral part of the manufacturing process for many industries.

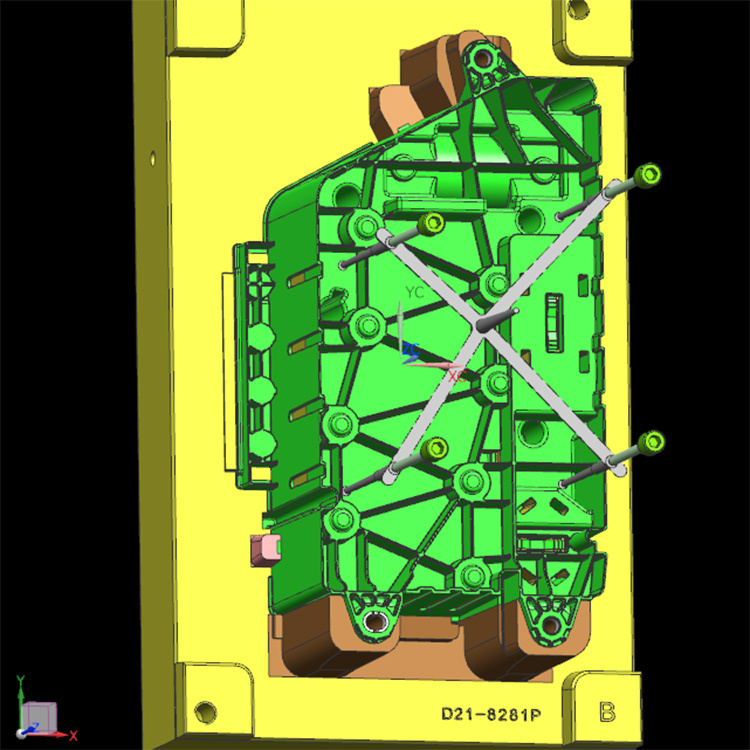

Application of 3D printing in mold industry

3D printing is a revolutionary technology that has the potential to revolutionize the mold industry. By using 3D printing, companies can create more complex molds with greater levels of accuracy, allowing them to produce higher quality products. 3D printing also allows companies to reduce lead time, as molds can be produced in a fraction of the time of traditional methods. Additionally, 3D printing enables custom molds to be produced quickly and cost-effectively, allowing companies to create products in shorter turnaround times. Finally, 3D printing can reduce waste in the molding process, as it produces molds with a much lower rate of defects. This can result in significant cost savings and improved efficiency.

Overall, 3D printing has the potential to revolutionize the mold industry by allowing companies to produce more complex molds with greater accuracy, reduce lead times, and reduce waste. By leveraging this technology, companies can produce higher quality molds more efficiently and cost-effectively than ever before.

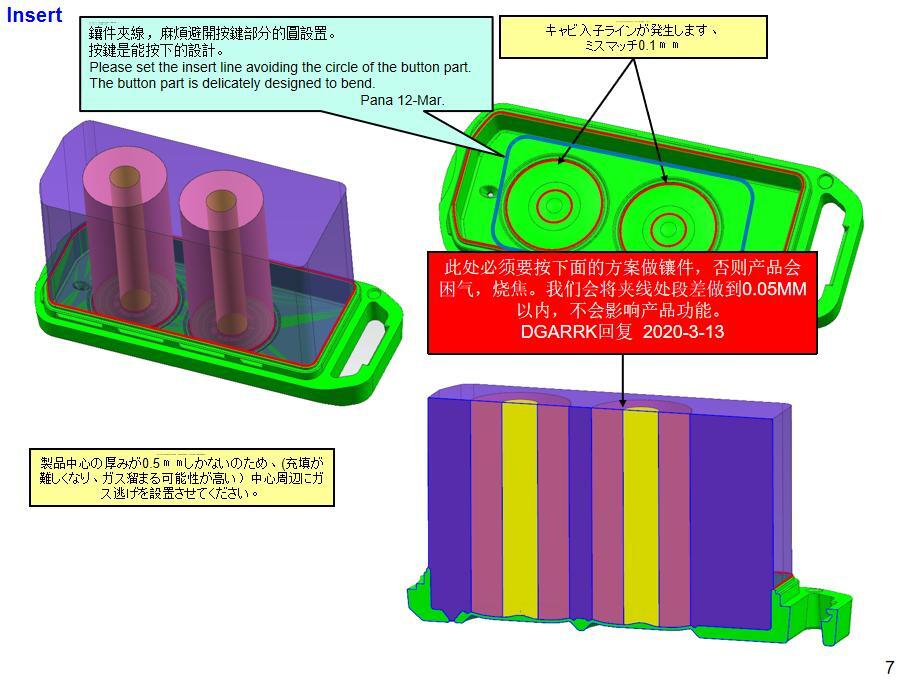

Precautions for using 3D printing technology in mold making

When using 3D printing technology in mold making, there are several precautions that should be taken to ensure the quality and accuracy of the final product.

First, it is important to use a 3D printer with a large build volume and high resolution to ensure the most accurate prints. Small build volumes and low resolutions can lead to imperfections in the printed mold. Additionally, it is important to make sure the printer is well calibrated and the software settings are optimized for the specific material being used.

Second, it is critical to ensure the 3D printing process is properly monitored. This includes regularly checking the temperature, humidity, and other environmental parameters, as well as monitoring the print head and nozzle for any signs of clogs or other issues.

Third, it is important to properly prepare the molds for use. This involves ensuring that any rough edges are smoothed out, as well as cleaning the molds to remove any residue or debris that could affect the quality of the final product.

Finally, it is important to use the correct 3D printing materials for the job. Different materials, such as thermoplastics, composites, and metal alloys, are better suited for different types of molds. It is important to research each material and select the one that best suits the needs of the project.

By following these precautions, 3D printing can be a reliable and accurate way to produce molds for a wide variety of projects.

How to improve the printing accuracy of 3D printing?

1. Use high-quality 3D printer: High-quality 3D printers are designed to produce accurate and consistent prints. Therefore, it is important to use a reliable 3D printer that is capable of producing accurate prints. It is also recommended to use a 3D printer that is regularly serviced and maintained to ensure that the printer is in top condition.

2. Use high-quality filaments: The quality of the filament used also affects the accuracy of the 3D prints. Using filaments with a consistent diameter and roundness will help to improve the accuracy of the 3D prints. It is also important to use filament that is designed for the specific type of 3D printer.

3. Perform regular maintenance of the 3D printer: Regular maintenance of the 3D printer ensures that the printer is working at its best. Checking and cleaning the nozzle, bed, and other parts of the 3D printer on a regular basis helps to ensure that the printer is working correctly and producing accurate prints.

4. Use the correct settings: The settings of the 3D printer should be adjusted according to the material and the model being printed. Increasing the printing speed too much can cause the printer to produce inaccurate prints. Therefore, it is important to use the correct settings for the material and model being printed.

5. Use a heated bed: A heated bed helps to improve the accuracy of the 3D print by providing a more even and consistent surface for the print to adhere to. It also helps to reduce the warping of the printed object.

6. Level the bed: It is important to level the bed of the 3D printer before printing. This helps to ensure that the print head is positioned correctly and that it is at the correct distance from the bed.

7. Increase the layer height: Increasing the layer height of the 3D print also helps to improve the accuracy of the 3D print. Increasing the layer height helps to reduce the number of layers and therefore reduces the chances of errors in the 3D print.

Our Certificates

By co-operating with Elite Mold, you have selected one of the most reliable ISO 9001 certified plastic mold manufacturer, Elite Mold as a plastic injection mold manufacturer specializing in plastic injection mold and supplying plastic injection molding services for plastic mold design, prototype makings, mold flow analysis, precise machining, OEM services, ODM services and so on, building custom plastic injection molding. We are committed to enhance the Process optimized and quality of service, shorten lead time and assist in lowering inventory, by providing new products every year to bring in continuous and higher profits for our clients. The ability to produce mold at the International standard, strong engineering and mold design capability, aggressive delivery, competitive pricing and business integrity continues to be the success factor of Elite Mold.