injection mold factory

Description

This is a precise injection mold, which is made within very tight tolerances up to +/-0.001MM;

The steels for mold bases & core/cavity inserts are supplied from LKM;

The molds are built at multi-cavity with DME or Hasco standards;

Some molds are with YUDO or MoldMasters Hot runner system;

The mold lifetime is long while the cycle time is short.

We are specializing in injection mold and supplying plastic injection molding services with mold design, prototype mold, Moldflow analysis, precise machining, and resourcing.

If you want to fina a plastic mold manufacturer or need injection molding services, welcome to Contact Us.

Custom Injection Molds

Material Selection for injection mold factory

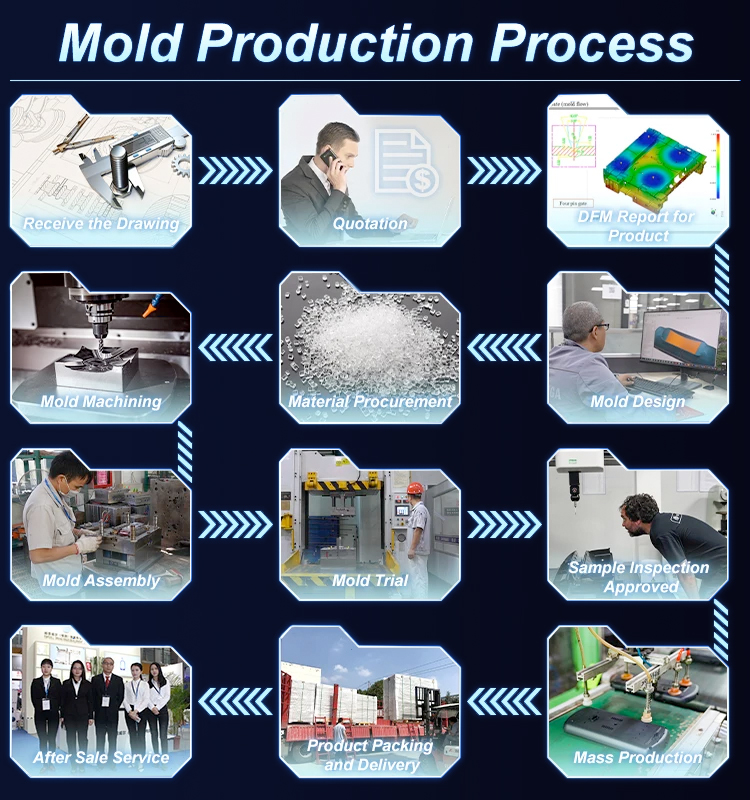

Prdduction Process for injection mold factory

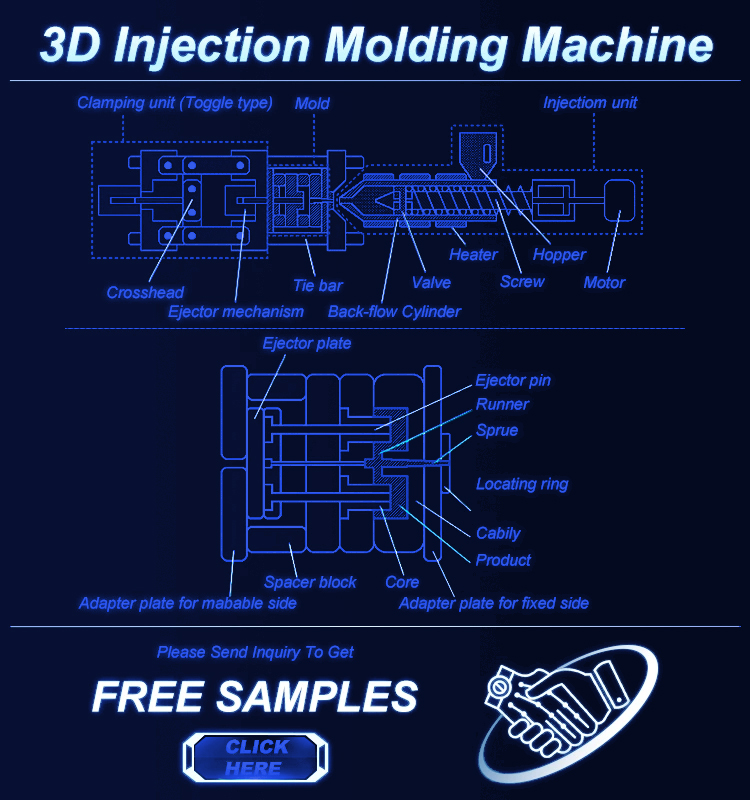

3D Injection Molding Machine for injection mold factory

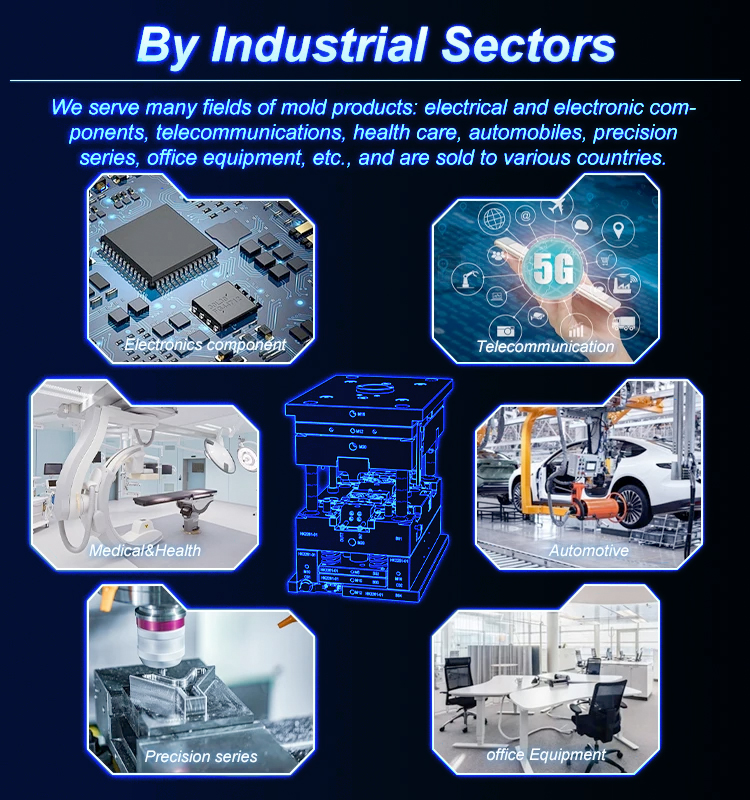

By Industrial Sectors

Plastic injection molding is the process used to produce low or high volumes of custom plastic parts for commercial and industrial use. From intricate automobile safety components to simple products, the applications span a range of industries.

In combination with skilled mold designers, software technology, and the use of expensive CNC machinery, Elite mold builds molds for plastic injection that are used to produce high quality molded plastic parts. Our injection molding experts look forward to working with you on your mold build project as the next step toward manufacturing your custom molded parts. If you’re looking for an injection mold factory, we have you covered.

Tag:injection molding supplier for automotive industry,plastic moulding manufacturers plastic injection mold

| Product Description | OEM plastic injection molding |

| Plastic Materials | PVC,PBT+GF,PC,PMMA,PBT,ABS,PET,PA66,PA6,PEEK,PC/ABS,PP,TPU,POM ,...etc. |

| Standard | ISO9001:2008 |

| Other materials | Rubber, Slilconce rubber, LSR,Aluminum, Zinc,Copper...Metal...etc. |

| Quality | RoSH and SGS standard |

| Feature | Non marking and Non flash |

| Size | According to your 2D, 3D Drawing |

| Unit price size: | To be discussed |

| Package | Standard exported Wooden box packed, Fumigation process(upon required) |

| Mold Building Lead Time | 4 - 5 weeks, Part measurement report (upon required) |

| Export Country | Oceania,America, Germany,Cape Verde...etc. |

| Experience | 15 years experience in plastic injection mold making and plastic parts produce. |

| To be discussed | In-Mold Decoration,Injection Mould,Plastic Mold,Overmould,2K Mould,Die-Casting Mould,Thermoset Mold,Stack Mold,Interchangeable Mold,Collapsible Core Mold,Die Sets,Compression Mold,Cold Runner System LSR Mold...etc. |

| Hot/ Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip...etc. |

| Mould Life | 5,000 to 1,000,000 Shots. (According to your working environment.) |

| Equipments | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available. |