plastic injection mold

What is Plastic injection mold?

A. Plastic injection mold refer to molds made of plastic (such as ABS, PE, PP, PA, PC, etc.). Plastic injection mold are mainly used for injection molding, used to make plastic products, and are important tools for the manufacture of plastic products

B. Plastic injection mold is the abbreviation of a combined mold for compression molding, extrusion molding, injection, blow molding and low foam molding. A series of plastic parts of different shapes and sizes can be processed through the coordinated change of the mold convex, concave mold and auxiliary molding system.

C. Plastic injection mold is the mother of industry, and the release of new products will involve plastic. All types of tools and products we all use in our daily production and lifestyle, ranging from the base from the machine device, the covering of the equipment equipment, to the small size of a screw, button and the shell of various household appliances, are all closely related to molds. The shape of the mold determines the shape of these products, and the processing quality and precision of the mold also determine the quality of these products. Due to the different materials, appearance, specifications and uses of various products, molds are divided into non-Plastic injection mold such as casting molds, forging molds, die-casting molds, and stamping molds, as well as Plastic injection mold.

The quality of Plastic injection mold has the following effects on product sales:

1. The quality of the mold is good, and the quality of the manufactured products is also higher, which will be recognized by consumers, thereby increasing the sales volume of the products.

2. The quality of the mold is good, which can increase the pouring speed and improve the production efficiency, thereby reducing the cost, and more in line with the requirements of the order, thereby improving the sales status of the enterprise.

3. Good quality molds can improve the reputation and word-of-mouth of the company, so as to better expand the market and increase sales.

4. The quality of the mold can improve the appearance and quality of the product, so as to better attract consumers, improve the competitiveness of the product, and increase the sales volume of the product.

What factors need to be considered when choosing a Plastic injection mold manufacturer for cooperation?

1. The production capacity of the plastic mold manufacturer: check the production history and relevant qualifications to determine the production capacity of the manufacturer.

2. Production equipment: Check the production equipment of the manufacturer to ensure the precision, stability and high efficiency of the equipment.

3. Price: Compare the quotations of multiple factories to determine the rationality of the price.

4. Delivery date: Check the delivery date of the manufacturer to determine whether it meets the requirements.

5. Service: Check the manufacturer's after-sales service and service quality to ensure that the after-sales service is of good quality.

6. Product quality: Check the manufacturer's product testing results to ensure that its product quality is reliable.

Plastic injection mold design considerations

1. Adopt the correct mold design scheme: When designing Plastic injection mold, the mold design scheme should be reasonably determined according to the size, shape, mold structure and other process requirements of the product.

2. Processing quality: The processing quality of Plastic injection mold is an important factor affecting the service life of the mold. High precision and smooth surface are required during processing. The splicing and bolt connection of mold components must be tight, and the structure must be firm to ensure the reliability and use of the mold. life.

3. Gate design: The gate design of the Plastic injection mold should consider the performance of the plastic, the flow characteristics of the plastic and the flow direction of the plastic, and determine the shape of the gate, the size of the gate, the eccentricity of the gate, the position of the gate, etc., to ensure that the plastic can into the mold correctly.

4. Mold maintenance: Plastic injection mold may be damaged by wear and deformation during use. Therefore, Plastic injection mold should be regularly maintained to ensure their service life.

What are the delivery standards for Plastic injection mold samples?

1. The mold should be accurately processed according to the requirements of the design drawings, and meet other requirements of this contract.

2. The delivered molds should have normal processing capabilities, and the materials should meet the requirements of relevant national standards.

3. The surface of the mold should be smooth and clean, without rust, damage or engraving marks.

4. The machining accuracy of the mold should meet the requirements of the drawings, and at least meet the accuracy requirements of DIN-ISO2768-mF.

5. The hinges, locks, guides, positioners, etc. required by the mold should be fully equipped and meet the requirements.

6. The mold should have a safe operation function and be equipped with a complete safety device. If necessary, a safety fence should be installed.

7. The mold should be equipped with a reasonable pneumatic and electrical system, and if necessary, a PLC system should be configured.

8. The mold should be equipped with a complete mold care system to meet the processing requirements of various materials.

9. The mold should meet the thermal deformation compensation requirements of Plastic injection mold processing.

10. The mold should be equipped with a good mold cooling system to ensure temperature stability during Plastic injection mold processing.

Industrial Chain Layout of Chinese Mold manufacturer

1.With the development of China mold industry, the industrial chain of China mold manufacturer has been continuously optimized. The industrial chain of China mold manufacturer mainly includes mold design and development, mold manufacturing, mold trial and mold application. The development of China mold industry has attracted many large and medium-sized domestic mold enterprises, and the industrial chain of China mold manufacturer has been further optimized.

2.Mold design and development is the core of mold manufacturing industry, and also the most creative and technological link. It is the most critical link in the process of mold manufacturing. In the stage of mold design and development, mold manufacturers need to design and develop molds according to the requirements of customers and the process requirements of products.

3.Mold manufacturing is the pillar of mold manufacturing industry and the key link of mold manufacturing industry. The key of mold manufacturing lies in the quality of mold. In this link, mold manufacturers need to use appropriate processing tools to precision process the mold according to the mold design drawing, in order to ensure the quality of the mold.

4.Mold trial is an important link in mold manufacturing industry and the most critical link in the process of mold manufacturing. The purpose of mold trial is to verify the quality of mold and the accuracy of mold, so as to ensure the quality of mold and ensure the efficient operation of mold.

5.Mold application is the final link in mold manufacturing industry and the most critical link in the process of mold manufacturing. The purpose of mold application is to install the mold on the production line to meet the customer's product production requirements and improve the customer's production efficiency.

6.With the continuous optimization of the industrial chain of China mold manufacturer, the layout of the industrial chain of China mold manufacturer is also continuously optimized. The layout of the industrial chain of China mold manufacturer not only includes mold design and development, mold manufacturing, mold trial, mold application, but also includes mold material procurement, mold maintenance and so on.

How to design a set of Plastic injection mold with good quality and precision

1. First of all, when designing a Plastic injection mold, it is necessary to consider the running speed of the mold, the structural size of the mold, and the material of the mold.

2. Secondly, when considering the mold material, the type and hardness of the material used should be determined according to the use characteristics of the mold to ensure the accuracy of the mold.

3. Then, the overall dimensions of the mold should be considered to ensure the accuracy of the mold.

4. Finally, when installing the mold, the fixity of the mold should be ensured so that the precision of the mold will not be affected.

What steps does the whole set of mold production include?

1. Customer order: order the type and size of the mold according to the customer's requirements;

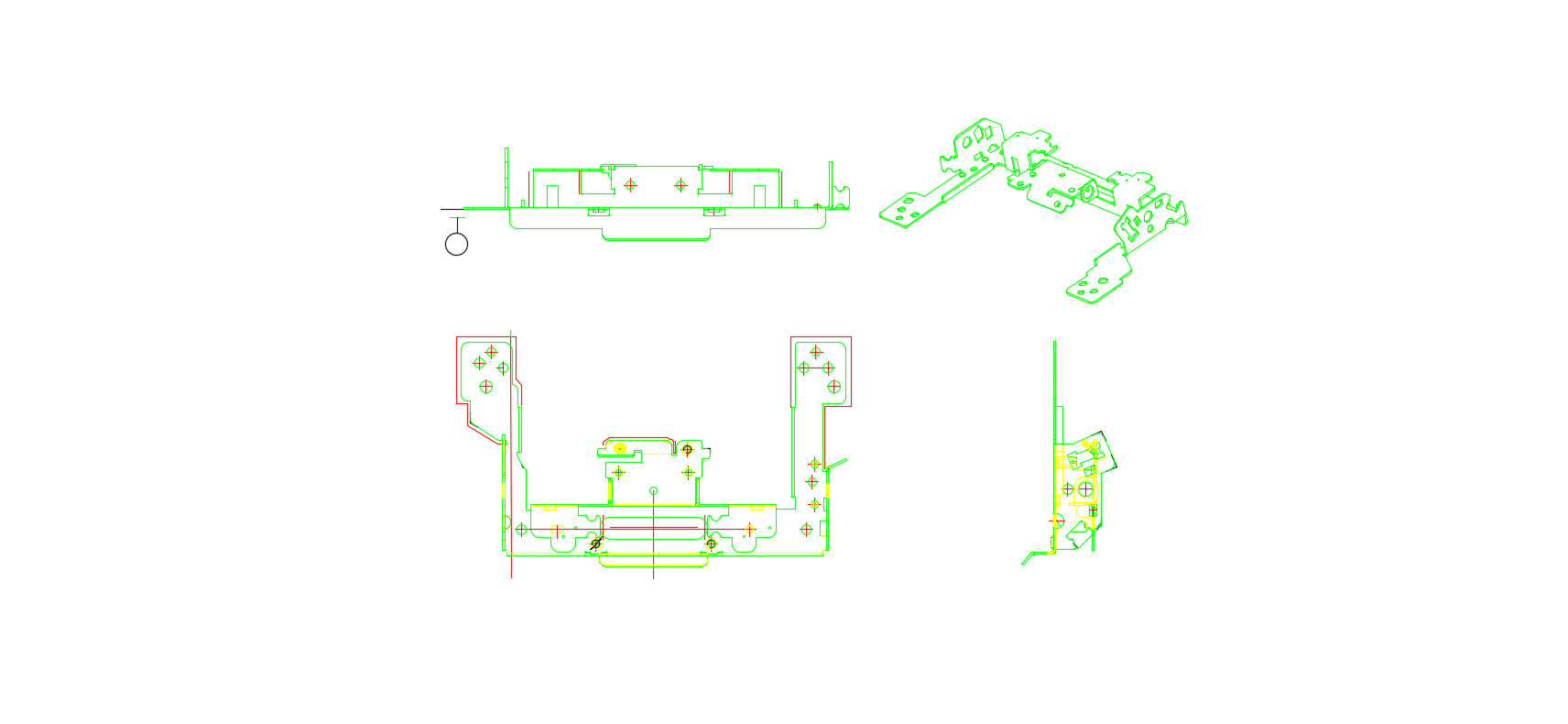

2. Mold design: According to the needs of customers, design the mold and determine the structure and material of the mold;

3. Mold processing: according to the mold design drawings, use CNC machine tools to process molds;

4. Mold heat treatment: through quenching, tempering and other methods, the surface strength of the mold can be improved and wear can be reduced;

5. Mold surface treatment: through electroplating, spraying, hot-plating, etc., the surface of the mold is more beautiful and the corrosion resistance is stronger;

6. Inspection: inspect the size, shape, function, etc. of the mold to ensure that the quality of the mold meets the requirements;

7. Packaging: Professionally package the qualified molds to ensure the safe transportation of the molds;

8. Delivery: send the mold to the place designated by the customer, and complete the delivery of the mold.

What raw materials are needed to make a set of Plastic injection mold?

The raw materials of Plastic injection mold include: rubber, plastic, polyurethane, gypsum, polyester resin, thermosetting resin, silicone rubber, anti-wear resin, glass fiber reinforced material, ceramic reinforced material, etc.

How to control the quality when purchasing Plastic injection mold raw materials?

1. Carefully review the quality inspection report of Plastic injection mold raw materials, and emphasize the delivery technical parameters in the inspection report. 2. Check the brand name of the raw material, whether the same kind of raw material is consistent. 3. Confirm whether the packaging of raw materials is tight, intact, free of damage, whether there is water seepage, and whether there is corrosion. 4. Check the appearance of the raw material, whether it is consistent with the specifications required by the raw material, and whether there is foreign matter mixed in. 5. Regularly check the mechanical properties of Plastic injection mold raw materials to ensure the requirements of quality standards.

The top 10 plastic injection mold manufacturer in China

1. ELITE MOLD (SHENZHEN) CO., LIMITED

2. Zhejiang Huangyan Hongqi Plastic Mould Co., Ltd.

3. Taizhou Huangyan Jinmatai Plastic Mould Co., Ltd.

4. Taizhou Huangyan Dayu Mould Co., Ltd.

5. Huangyan Yougo Mould & Plastic Co., Ltd.

6. Taizhou Huangyan Yuzhuo Mould & Plastic Co., Ltd.

7. Taizhou Huangyan Yide Mould Co., Ltd.

8. Taizhou Huangyan Guanhai Mould Co., Ltd.

9. Taizhou Huangyan Jingmei Mould Co., Ltd.

10. YANGFAN MOULD

Our Certificates

By co-operating with Elite Mold, you have selected one of the most reliable ISO 9001 certified plastic mold manufacturer, Elite Mold as a plastic injection mold manufacturer specializing in plastic injection mold and supplying plastic injection molding services for plastic mold design, prototype makings, mold flow analysis, precise machining, OEM services, ODM services and so on, building custom plastic injection molding. We are committed to enhance the Process optimized and quality of service, shorten lead time and assist in lowering inventory, by providing new products every year to bring in continuous and higher profits for our clients. The ability to produce mold at the International standard, strong engineering and mold design capability, aggressive delivery, competitive pricing and business integrity continues to be the success factor of Elite Mold.